Emmanuel Segura-Cárdenas (Tecnologico de Monterrey, Escuela de Ingenieria y Ciencias) and Luis Fernando Velásquez-García (MIT) detail the results of a recent study in ‘Additively Manufactured Robust Microfluidics via Silver Clay Extrusion,’ explaining how they created a proof-of-concept microfluidic capable of decomposing hydrogen peroxide.

While most microfluidics are composed of silicone, such materials are incapable of handling high temperature or pressure—and they are not very compatible with solvents. Metal could be considered a suitable choice for the development of sturdy microfluidic devices, but currently, most of that technology is geared toward the creation of thin films and wafer bonding.

“In addition, fabrication approaches such as electric discharge micromachining [9] and micro milling [10] have been explored to implement metal microfluidics, but these manufacturing processes are very expensive, very slow, and require specialized tooling.”

Today, microfluidics are often accompanied by a variety of different 3D printing techniques, featured in research developing new sensors, organs-on-chips, and enhancing other processes like bioprinting. More standard 3D printing techniques like FFF have been used to develop microfluidics; however, most lack catalytic properties and can, again, only manage a slight amount of pressure or increase in temperature.

In this study, the researchers endeavored to use metal extrusion with clay, relying on silver clay to produce sturdy, affordable microfluidics. Silver clay is known to be compatible with many different microfluidics, offering benefits such as:

- High thermal features

- Electrical conductivity

- Chemical resistance

- Catalytic properties

Green and annealed samples were fabricated for testing in the study, with some concern over shrinkage. While the authors mainly attributed that to the printing process, they found the ‘mismatch between actual dimensions and intended dimensions’ to also be possible due to pressure on the clay syringe, a lack of XY pixels, or high-temperature annealing.

The researchers 3D printed step pyramids in 150 μm-thick and 200 μm-thick layers. In all, 15 structures were 3D printed, with the team measuring them randomly in four points within each step.

“The steps were centered around the vertical axis of the pyramid, and the separation between the edges of adjacent steps was set at 400 μm in the CAD files,” stated the authors. “Metrology of the test structures evidences linearity between the CAD and printed in-plane features for both green and annealed structures. On average, the dimensions of the green structures are 93% the CAD values, while the dimensions of the annealed structures are 81% the CAD values (i.e. the in-plane features of the annealed structures shrink about 13 percent from the dimensions of the green structures).

“No significant difference between measurements in the X and Y directions was found, although the structures made with the coarser slicing (i.e. 200 μm layer height) have associated less size variation and closer correspondence to the CAD files.”

Stair-like structures were also fabricated, measured, and characterized. Each sample featured nine steps on a 1 mm-thick base plate.

“In all cases, we found that the height of the base of the printed stair structure was equal to 0.98 mm instead of 1 mm, probably reflecting the out-of-plane offset typically present in the first layer printed by an FFF 3D printer,” stated the authors.

Six long, narrow wire samples were printed and annealed for characterization of electrical resistivity.

“The least-squares fitting of the data shows a linear dependence between the length of the wire and its electrical resistance, in agreement with Ohm’s law,” stated the authors.

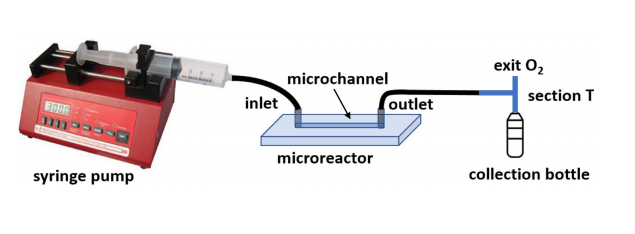

In fabricating the microreactor, the researchers reported 12 minutes for printing, four hours for annealing, and a total cost of $25.

“The microreactor operates as predicted by the reduced-order modeling, attaining 87% decomposition efficiency for 5 μL/min flow rate of hydrogen peroxide with 30% w/w initial concentration,” stated the authors.

“The experimental results are in agreement with our modeling, including the complete decomposition of hydrogen peroxide with initial w/w concentration up to 1.8 % and 5 μL/min flow rate, and 87% decomposition efficiency when the initial hydrogen peroxide w/w concentration is increased to 30%,” concluded the researchers.

“The reported 3D printing method is compatible with heat transfer and microreactor microfluidic applications, e.g. compact heat exchangers, nanosatellite monopropellant rockets, and handheld steam generators for biological decontamination.”

What do you think of this news? Let us know your thoughts; join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘Additively Manufactured Robust Microfluidics via Silver Clay Extrusion’]

If you're looking to get an architectural rendering quote in the USA, our service provides a simple and efficient process to obtain the best pricing tailored to your project. Through our platform, you can easily submit your project details and receive a competitive quote from our team of experts. We offer high-quality 3D renderings for both interior and exterior designs, helping you bring your architectural visions to life with stunning precision. With our support, you can be confident in receiving professional services at affordable prices, without the hassle of dealing with multiple vendors.

Getting an accurate architectural rendering quote has never been easier. Through our portal, you’ll have direct access to a streamlined process where we guide you step by step, ensuring all your needs are met. Our 3D rendering experts work closely with you to ensure the final product matches your expectations, whether it’s for residential, commercial, or mixed-use developments. Trust our platform to provide you with the best possible rates and results, all with a quick turnaround time and exceptional customer support.