In ‘Applying Neural-Network-Based Machine Learning to Additive Manufacturing: Current Applications, Challenges, and Future Perspectives,’ authors Xinbo Qi, Guofeng Chen, Yong Li, Xuan Cheng, and Changpeng Li investigate how machine learning (ML) and neural network algorithms (NN) can be applied to additive manufacturing.

While the many benefits of AM processes continue to be uncovered, availing themselves to countless industries today, there are still numerous drawbacks and scenarios for defects which continue to challenge users around the world—from porosity to anisotropic microstructures, to distortion, and more.

Prototypes may not always require perfection as simple models, however, parts meant for true functional, industrial use must be strong and produced without threat to their overall integrity. The authors point out the importance of understanding the following:

- Powder’s metallurgical parameters

- 3D printing process

- Microstructure

- Mechanical properties of AM parts

In machine learning, the NN algorithm is only increasing in popularity for use and is currently under ‘rapid development,’ most often employed in computer vision, voice recognition, language processing, and self-driving vehicles. It is a supervised type of ML, operating with labeled data, and within additive manufacturing is showing good suitability for ‘agile manufacturing’ in industry.

“The NN has exerted a deep and wide impact on all value chain innovation in industry—from product design, manufacturing, and qualification to delivery—and it is believed that the impact of NN will be increasingly intensive,” state the researchers.

The most common types of NNs are:

- Multilayer perceptron (MLP)

- Convolutional neural network (CNN)

- Recurrent neural network (RNN)

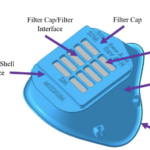

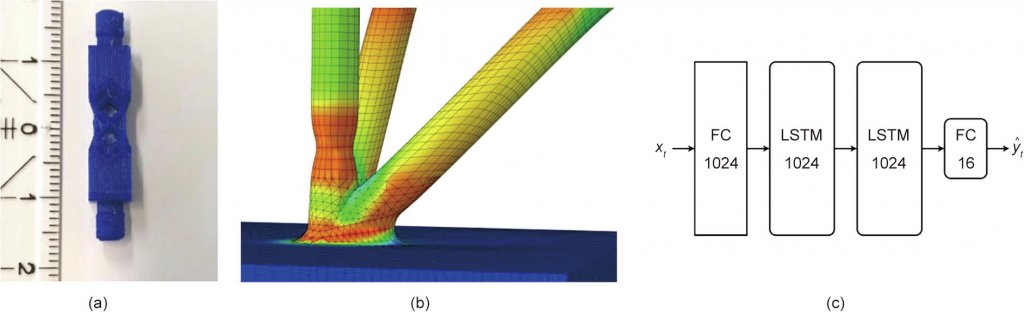

In design for additive manufacturing, the engineers create a CAD model which was then applied in analytical software for AM simulation. Many deviations are found, however, when comparing the models to the actual 3D prints—often due to stress during production and resulting distortion. The researchers state that they usually perform compensation for better accuracy.

Sensors have been created for the hardware and software, and a variety of different sensors can be used for in situ measurements too.

“The scope of this work covers many variants of NNs in various application scenarios, including: a traditional MLP for linking the AM process, properties, and performance; a convolutional NN for AM melt pool recognition; LSTM for reproducing finite-element simulation results; and the variational autoencoder for data augmentation. However, as they say, ‘every coin has two sides.’

“It is difficult to control the quality of AM parts, while NNs rely strongly on data collection. Thus, some challenges remain in this interdisciplinary area. We have proposed potential corresponding solutions to these challenges and outlined our thoughts on future trends in this field,” concluded the researchers.

Machine Learning is often connected with 3D printing, from varying monitoring methods and smarter metal additive manufacturing, to construction. What do you think of this news? Let us know your thoughts! Join the discussion of this and other 3D printing topics at 3DPrintBoard.com.

[Source / Images: ‘Applying Neural-Network-Based Machine Learning to Additive Manufacturing: Current Applications, Challenges, and Future Perspectives’]

If you're looking to get an architectural rendering quote in the USA, our service provides a simple and efficient process to obtain the best pricing tailored to your project. Through our platform, you can easily submit your project details and receive a competitive quote from our team of experts. We offer high-quality 3D renderings for both interior and exterior designs, helping you bring your architectural visions to life with stunning precision. With our support, you can be confident in receiving professional services at affordable prices, without the hassle of dealing with multiple vendors.

Getting an accurate architectural rendering quote has never been easier. Through our portal, you’ll have direct access to a streamlined process where we guide you step by step, ensuring all your needs are met. Our 3D rendering experts work closely with you to ensure the final product matches your expectations, whether it’s for residential, commercial, or mixed-use developments. Trust our platform to provide you with the best possible rates and results, all with a quick turnaround time and exceptional customer support.