Swiss high-tech company FEMTOprint, dedicated to contract manufacturing of 3D printed microdevices in glass and other transparent materials, worked with Galatea Lab, Instant Lab and the Jules-Gonin Ophthalmic Hospital this past winter to explore how 3D printing could be used to further innovate the med-tech industry. Now, the company is lending its talents to the production of 3D printed glass molds for droplet microfluidic chips. Its technology can grow the experimental capabilities of droplet microfluidic chips

The research, detailed in a recent case study, was carried out alongside researchers from the Leibniz Institute for Natural Product Research and Infection Biology (Leibniz HKI) in Germany.

“We have been working together with FEMTOprint for more than 2 years now, as we see in their technology potential to expand the possibilities of our microfluidic structure designs,” said Miguel Tovar with the Leibniz HKI and Hans Knöll Institute. “They offer the best methodology for the fabrication of 3D structures with micrometric resolution without requiring unsurmountable pay or time walls. Contrarily, they have become an additional team member. We look forward to further collaborations.”

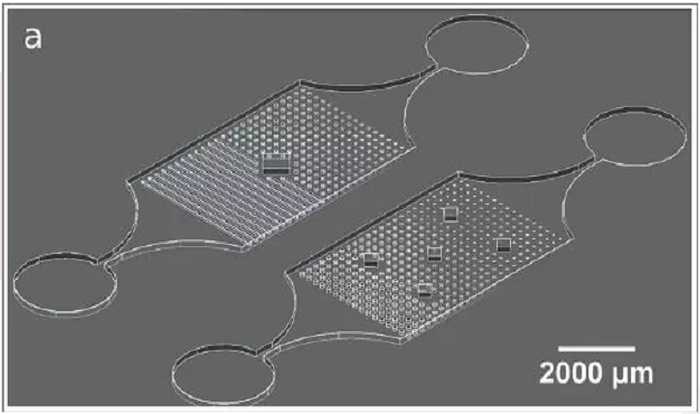

The collaborative research team – made up of scientists from Leibniz HKI, Friedrich Schiller University, the Ilmenau University of Technology, FEMTOprint, and the Fraunhofer Institute for Applied Optics and Precision Engineering (Fraunhofer IOF) – fabricated 3D PDMS (silicone rubber) chips for droplet microfluidics by using FEMTOprint’s innovative glass technology to make 3D printed glass molds. FEMTOprint’s direct writing process makes it possible to create microfluidic designs with different levels, continuously changing heights, and complex 3D shapes, along with sub-micrometric resolution.

This new technique, when paired with simple PDMS replica molding, can provide users with a solution for non-specialized and specialized labs in order to customize and expand microfluidic experimentation.

The researchers published a paper, titled “3D-glass molds for facile production of complex droplet microfluidic chips,” in the Biofabrication journal; authors are Miguel Tovar, Thomas Weber, Sundar Hengoju, Andrea Lovera, Anne-Sophie Munser, Oksana Shvydkiv, and Martin Roth.

The abstract reads, “In order to leverage the immense potential of droplet microfluidics, it is necessary to simplify the process of chip design and fabrication. While polydimethylsiloxane (PDMS) replica molding has greatly revolutionized the chip-production process, its dependence on 2D-limited photolithography has restricted the design possibilities, as well as further dissemination of microfluidics to non-specialized labs. To break free from these restrictions while keeping fabrication straighforward, we introduce an approach to produce complex multi-height (3D) droplet microfluidic glass molds and subsequent chip production by PDMS replica molding.”

This new technique allows for novel new possibilities in the industry, which can be exploited with microfluidics applications and droplets. As of right now, no other simple methodology but this one exists that would allow architectures with structures from 15 µm to hundreds of micrometres in all dimensions to be produced.

3D printed glass molds can be used to combine the replication and ease of production that soft lithography is capable of with the advantages of high-resolution prototyping. Additionally, it can facilitate fabrication of multilevel structures – even ones with gradients of confinement, which can make important droplet microfluidic operations better.

According to FEMTOprint, 3D printed glass structures “represent a negative part,” and they can also be directly used as chips by bonding them to a PDMS slab or glass; this makes it possible to utilize structures, like mirrors, lenses, and filters, that replica molding cannot recreate.

The 3D printed glass mold can pack 192 nozzles into a design that’s 25 mm long and 4 mm wide, including all inlets and outlets, which will generate monodisperse droplets of ø70 µm. It’s also easy to scale this structure so it is capable of holding 1,000 nozzles in a 6.5 cm structure. Now, thanks to possibilities opened up by this research, chip fabrication doesn’t have to be the bottleneck for non-microfluidic labs adopting microfluidic approaches. Instead, it should be looked at as a way to implement novel functionalities, like optical fiber integration for fluorescence detection.

Discuss this story and other 3D printing topics at 3DPrintBoard.com or share your thoughts in the Facebook comments below.

[Images: Miguel Tovar, Leibniz Institute]

If you're looking to get an architectural rendering quote in the USA, our service provides a simple and efficient process to obtain the best pricing tailored to your project. Through our platform, you can easily submit your project details and receive a competitive quote from our team of experts. We offer high-quality 3D renderings for both interior and exterior designs, helping you bring your architectural visions to life with stunning precision. With our support, you can be confident in receiving professional services at affordable prices, without the hassle of dealing with multiple vendors.

Getting an accurate architectural rendering quote has never been easier. Through our portal, you’ll have direct access to a streamlined process where we guide you step by step, ensuring all your needs are met. Our 3D rendering experts work closely with you to ensure the final product matches your expectations, whether it’s for residential, commercial, or mixed-use developments. Trust our platform to provide you with the best possible rates and results, all with a quick turnaround time and exceptional customer support.