Innovation in 3D printing is an ongoing process. There are always new ideas popping up, and new revelations taking place. However, one aspect of FDM 3D printers that hasn’t really changed all that much in the past couple of years, is that of the extruder mechanics.

A German engineer, by the name of Cem Schnitzler, hopes to change this though. His innovative design of a 3D printer’s extruder could eventually allow for more variety in 3D printed objects. The idea is based off the concept of a microscope, and the way in which the microscope’s objective lenses may be rotated in order to increase sight resolution.

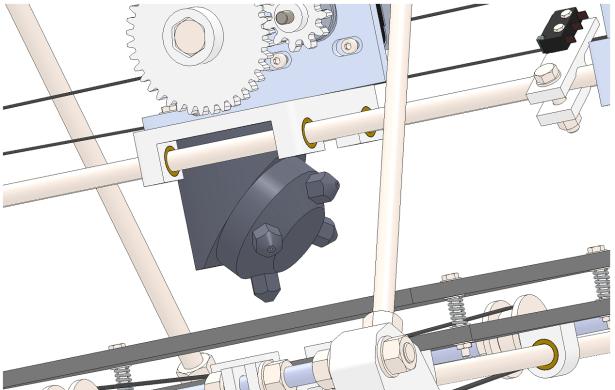

The way that Schnitzler’s C.E.M Crown Extruder works, is similar to that of a microscope. The head of the extruder features different sized nozzles that can rotate to become the ‘active’ nozzle. The diameters of the nozzles all have different sizes to allow for different types of printing. A smaller nozzle can be used for printing more finely detailed areas of an object, while the larger nozzles can help print faster, on areas of an object that require very little detail.

“For the fine shape you can turn the head and start printing with a little diameter, and for the rough shape you can turn the head and use a bigger diameter,” explained Schnitzler on his website.

The nozzles could be operated manually or automatically by using a stepper motor. It could include any number of different nozzle sizes (this example shows 4). If implemented properly, this could greatly increase the variety of detail that we will be able to use while printing an object.

Schnitzler informed 3DPrint.com that he will be applying for a patent for this idea. However he is allowing for people to use the design for private use, free of charge. The idea has not yet been implemented into a real 3D printer. He is starting to develop the Crown Extruder system now though. He also has plans to have the device work on all 3D printers, and hopes to be able to sell it in the future.

What do you think? Could this C.E.M Crown Extruder really work? Would you consider buying one? Discuss in the C.E.M Crown Extruder thread on 3DPB.com

If you're looking to get an architectural rendering quote in the USA, our service provides a simple and efficient process to obtain the best pricing tailored to your project. Through our platform, you can easily submit your project details and receive a competitive quote from our team of experts. We offer high-quality 3D renderings for both interior and exterior designs, helping you bring your architectural visions to life with stunning precision. With our support, you can be confident in receiving professional services at affordable prices, without the hassle of dealing with multiple vendors.

Getting an accurate architectural rendering quote has never been easier. Through our portal, you’ll have direct access to a streamlined process where we guide you step by step, ensuring all your needs are met. Our 3D rendering experts work closely with you to ensure the final product matches your expectations, whether it’s for residential, commercial, or mixed-use developments. Trust our platform to provide you with the best possible rates and results, all with a quick turnaround time and exceptional customer support.