Collagen Based Scaffold

Most biomaterials all are vastly different than each other in interesting ways. For those who have kept up with this series, it is safe to assume we still have a bunch of materials to analyze and understand. The field of biomaterials is vast and we need to understand all our options for bioprinting. Most additive manufacturing industries are comparatively simple and have polymer standards when it comes to 3D printing. So the materials are often derivatives and are similar to existing well-understood materials. This is not the case yet in bioprinting because of how complex biology is. We cannot limit the scope of materials because different materials are beneficial for a wide array of purposes within bioprinting. Today we will take a look into how gelatin is used in bioprinting.

Gelatin is a translucent, colorless, brittle (when dry), substance that is derived from collagen obtained from various animal body parts. It is also referred to as hydrolyzed collagen, collagen hydrolysate, gelatine hydrolysate, hydrolyzed gelatine, and collagen peptides. It is typically used as a gelling agent in food, medications, photographic films, and cosmetics.

Gelatin formation through collagen hydrolysis

It is important to understand the terminology of a hydrolyzed collagen within bioprinting. Collagen is the most abundant protein in the body and helps give structure to our hair, skin, nails, bones, ligaments, and tendons in our body. Collagen allows us to move, bend and stretch. Collagen also keeps our hair shiny, our skin glowing, and our nails strong. It is an essential protein.

Collagen cannot be absorbed by the body unless it is hydrolyzed. This means that the process of hydrolysis must occur before it can be effectively absorbed. Water is used to break down a collagen into its components. These components are amino-acids such as glycine, proline, hydroxyproline, and arginine, all of which help our body’s connective tissue, skin, hair, nails, as well as gut health.

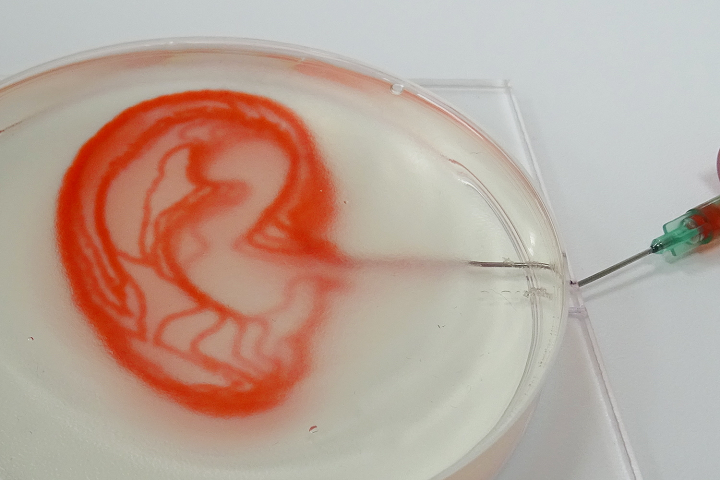

Earlobe Vasculator Structure from Gelatin

With all that info stuffed down your throats, I am sure you are wondering how is this relevant for bioprinting. Typically gelatins are used to create hydrogels. We have discussed hydrogels in general before in this series. These particular gelatin hydrogels have important properties. They have excellent biocompatibility due to the amount of amino-acid components embedded within them. They have rapid degradability due to how they break down in reaction to water. They lastly have non immunogenicity due to how readily available the components of a gelatin are within the human body.

The biggest pain point for gelatin hydrogels is the melting point temperature. Gelatins are thermosensitive polymers. This causes tensile strength to sharply reduce once the material is above 28 degrees Celsius. The strength of a gelatin is also dependent on other additives that are used in combination with it.

This is only us scratching the surface on gelatin as a biomaterial. Through this series we hope that people realize that we are only giving small pieces of info out. We encourage you as a reader to follow up and learn more from reading and expanding your knowledge. Maybe an interest for bioprinting will lead to you studying more biochemistry and a variety of topics. We will continue to give you small sample sizes of the vast world within biology and how it can be applied to bioprinting. Leave some comments even on some things you would like to know about as a reader.

If you're looking to get an architectural rendering quote in the USA, our service provides a simple and efficient process to obtain the best pricing tailored to your project. Through our platform, you can easily submit your project details and receive a competitive quote from our team of experts. We offer high-quality 3D renderings for both interior and exterior designs, helping you bring your architectural visions to life with stunning precision. With our support, you can be confident in receiving professional services at affordable prices, without the hassle of dealing with multiple vendors.

Getting an accurate architectural rendering quote has never been easier. Through our portal, you’ll have direct access to a streamlined process where we guide you step by step, ensuring all your needs are met. Our 3D rendering experts work closely with you to ensure the final product matches your expectations, whether it’s for residential, commercial, or mixed-use developments. Trust our platform to provide you with the best possible rates and results, all with a quick turnaround time and exceptional customer support.