The Blueprinter development process began in 2008 when Frederik Tjellesen and Anders Hartmann, as engineering students at the Technical University of Denmark, wrote a thesis which attempted to demonstrate that it would be possible to make 3D printers available to smaller businesses. At the time, few companies were prepared to take on the costs involved in printing 3D prototypes, but Tjellesen and Hartmann were determined to make the technology available to manufacturers, architects, engineers and educational institutions.

As the pair began their manufacturing efforts in 2009, little did they know it would be another three years until the first Blueprinter was introduced to the public in Birmingham. But by summer 2013, the pair had completed their first beta program and twelve printers were installed.

As of January 2014, the team had made the first Blueprinter available to the market. Now the Danish 3D printing pioneers have launched the next generation of their machine.

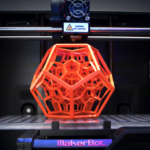

This latest machine, Blueprinter M3, includes smoother lines and an increased build volume. It’s also been highly optimized for daily use and to be much more user-friendly. The company says the noise output of the M3 has been reduced by some 60% meaning that it is now as quiet as a standard 2D printer – and it uses less power as well. Additionally, enhanced mechanisms used to drive the powder shovels and new powder drawers make the M3 more capable of printing accurate and more detailed parts. An increased build volume – now 200mm x 157mm x 150mm – allows for the production of multiple parts in a single print run as well.

Last but not least, a stiffer chassis has been developed which represents a 40% improvement over the previous version, a new lid hinge mechanism with damping has been installed and the company says that this latest design improves service access for maintenance tasks as well.

The M3 uses what the company calls SHS – Selective Heat Sintering – a technology which utilizes a thermal printhead rather than the laser used in a typical SLS machine. This thermal printhead applies heat to layers of thermoplastic powder within the build chamber and is capable of building objects with complex geometrical shapes which feature a minimum wall thickness of 1 mm.

Blueprinter says that, once a print run is complete, the entire build can be removed and the printer resets to begin printing again within 5 minutes. The Blueprinter M3, the cleaning station and 12 kgs of M-Flex powder retail for € RRP 25,450.00 or a little over $28,000, putting this machine somewhere in the middle of the 3D printer market. Let us know your thoughts on this new machine in the Blueprinter M3 forum thread on 3DPB.com. Be sure to check out the video below:

If you're looking to get an architectural rendering quote in the USA, our service provides a simple and efficient process to obtain the best pricing tailored to your project. Through our platform, you can easily submit your project details and receive a competitive quote from our team of experts. We offer high-quality 3D renderings for both interior and exterior designs, helping you bring your architectural visions to life with stunning precision. With our support, you can be confident in receiving professional services at affordable prices, without the hassle of dealing with multiple vendors.

Getting an accurate architectural rendering quote has never been easier. Through our portal, you’ll have direct access to a streamlined process where we guide you step by step, ensuring all your needs are met. Our 3D rendering experts work closely with you to ensure the final product matches your expectations, whether it’s for residential, commercial, or mixed-use developments. Trust our platform to provide you with the best possible rates and results, all with a quick turnaround time and exceptional customer support.