…. Tweeted just moments ago by Mike Chen, Co-Founder of Made In Space:

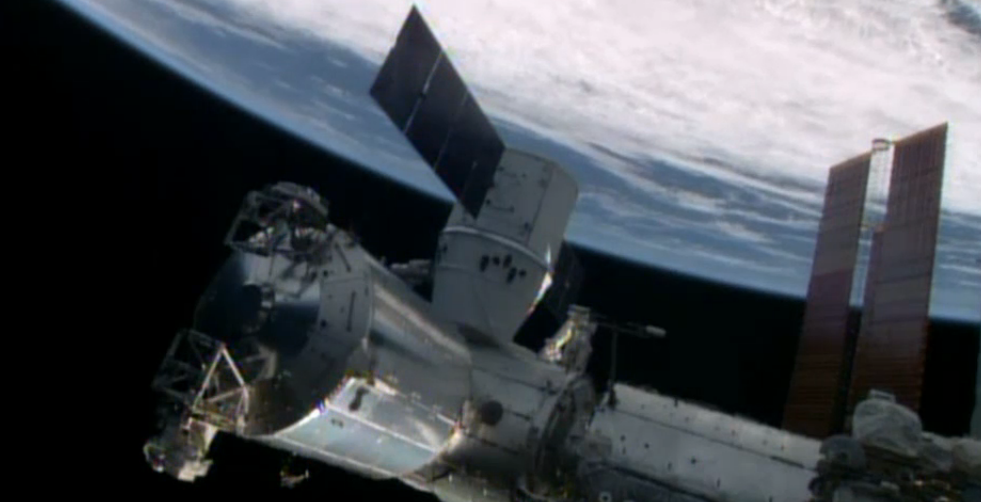

“The Dragon hatch is open. This marks the first moment when the ISS crew could access the @MadeInSpace 3D printer.”

Amidst Twitter chatter, news chatter, TV coverage, and coverage all over the internet – 3D Printing technology has been launched into the stratosphere and has just landed!

With the SpaceX Dragon supply freighter being bolted into place upon arrival at the International Space Station today, it was technological history in the making—a marker for sure, as that little device may have a lot to do with helping us progress in being able to survive under pressure in space on future missions.

This afternoon, astronauts received their much discussed Made in Space Zero-G 3D printer, delivered via the SpaceX Dragon rocket for NASA, to astronauts at the International Space Station. Along with 5,000 lbs. of supplies, including some live ones in the form of mice and flies for biological research, they also received fresh spacesuit batteries, and a $30 million instrument to measure ocean wind. But back to our printer…

This is not just your basic printer that was sealed up in a box and sent by courier off to outer space. Created by Northern California company, Made in Space, the 3D printer was put to the test by NASA with over 20,000 print hours of testing. It performed so well that tests were completed early, allowing the printer to be delivered ahead of time.

The 3D printer, barely a foot tall, 9½ inches wide and 14½ inches wide, will be installed in the Microgravity Science Glovebox (MSG) on the station, where it will begin printing demo parts such as tools and parts which will be viewable on video at NASA.gov. The parts it churns out will be later assessed for viability and strength. “The printer will not be installed immediately,” Mike Chen of Made in Space told 3DPrint.com. “NASA will schedule the printer to print, taking into account all other astronaut activity.”

Scientists and entrepreneurs are making it clear that additive manufacturing has a strong hold on technological progress, as there are expansive plans for 3D printing in space. With this first mission as a preliminary foray, there are imminent plans to setadditional machines in space.

The hope and goal is that astronauts will be able to replace parts that break, as well as using printers to make parts to create entire stations, for example, in visiting Mars. “If we’re really going to set up shop on Mars,” we have to do this, Jeff Sheehy, NASA’s senior technologist, said Friday. “We really can’t afford to bring everything we need for an indefinite amount of time. We’ll need to get to the point where we can make things that we need as we go.”

Technology companies can do all the marketing in the world—but sending a 3D printer into space has sparked the interest and curiosity of everyone reading or watching the news today! Did you watch the launch? What do you think of astronauts printing parts in space? Join the conversation in the 3D Printer in Space forum thread at 3DPB.com.

The Dragon will remain at the ISS for about a month, will be filled with science experiments performed by the astronauts, and then sent back to Earth.

If you're looking to get an architectural rendering quote in the USA, our service provides a simple and efficient process to obtain the best pricing tailored to your project. Through our platform, you can easily submit your project details and receive a competitive quote from our team of experts. We offer high-quality 3D renderings for both interior and exterior designs, helping you bring your architectural visions to life with stunning precision. With our support, you can be confident in receiving professional services at affordable prices, without the hassle of dealing with multiple vendors.

Getting an accurate architectural rendering quote has never been easier. Through our portal, you’ll have direct access to a streamlined process where we guide you step by step, ensuring all your needs are met. Our 3D rendering experts work closely with you to ensure the final product matches your expectations, whether it’s for residential, commercial, or mixed-use developments. Trust our platform to provide you with the best possible rates and results, all with a quick turnaround time and exceptional customer support.